Linen, an ancient long-fibered plant, has conquered the world with its exceptional technical properties. Rooted in history, flax is celebrated today for its strength, lightness, durability and multiple industrial applications. In this in-depth article, we’ll explore flax’s technical characteristics in detail, highlighting its role in fields as varied as textiles, industry and construction.

An exceptionally long, strong fiber

Flax derives its exceptional strength from the length of its technical fibers. With an average length of 20 to 90 centimeters, these fibers often exceed those of cotton. This characteristic gives linen remarkable mechanical strength, particularly tensile strength, surpassing that of many other natural fibers. This makes flax the preferred choice for textiles requiring increased strength, such as ropes, canvas and technical flax fiber reinforcements for composite materials.

Case in point : Linen marine ropes have been used for centuries for their exceptional strength and durability. Ancient sailors relied on linen ropes to withstand the intense forces encountered on the high seas.

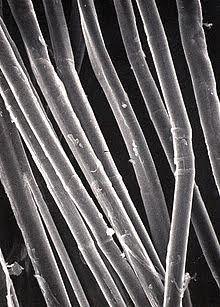

Microstructure and chemical composition of natural fiber

Flax’s microstructure, characterized by hollow, elongated fibers, is a key to its technical properties. These fibers are composed mainly of cellulose (70-85%), lignin (10-15%) and pectin (1-5%). Cellulose gives flax its mechanical strength.

Case in point : when flax fibers are observed under the microscope, their hollow-tube structure is obvious. These capillary channels play an essential role in flax’s moisture absorption and breathability.

Moisture absorption and thermal control

Flax stands out for its exceptional moisture absorption capacity. It can absorb around 16% of its weight in water without appearing wet, making it ideal for garments in a variety of climates. This characteristic enables linen to regulate body temperature, wicking away excess moisture and offering optimum comfort.

Case in point : linen garments are prized in hot climates for their ability to absorb perspiration and keep you feeling cool. Linen sheets are also appreciated for their comfort on warm nights.

Résistance aux UV et à l’Abrasion

Linen’s resistance to ultraviolet (UV) rays makes it a preferred choice for a variety of applications requiring sun protection. Studies show that linen textiles can block up to 80% of UV rays, providing a natural barrier against the sun’s harmful effects. This characteristic makes it the material of choice for outerwear, parasols and sails, where sun protection is crucial. Linen is also highly resistant to abrasion, making it the fiber of choice for a wide range of furnishing fabrics (cushions, sofas, armchairs).

Case in point : traditional straw hats, often made from linen fibers, have been used for centuries to protect the head and face from the sun’s rays.

Lightness, suppleness and comfort

Linen’s lightness is one of its most appreciated characteristics. With a density of around 1.4 g/cm³, linen is one of the lightest natural fibers. This lightness, combined with its natural suppleness, gives linen products a soft texture and pleasant feel. Linen garments are therefore known for offering exceptional comfort, providing a feeling of lightness and freedom of movement.

Case in point : Travel clothing is often made from linen because of its lightness and ease of folding without wrinkling, offering travelers a blend of practicality and comfort.

Industrial processing and varied applications

Flax processing, from field to final product, involves meticulous procedures. After harvesting, the flax stalks undergo a retting process to partially separate the flax fibers from the shives, followed by scutching and combing to obtain fine, regular fibers. These fibers are used in a multitude of industrial applications, far beyond the textile field.

Case in point : the construction industry uses flax-based composite materials to improve product strength while reducing weight. Lightweight, durable construction panels are thus created, contributing to the sustainability of buildings.

Soundproofing : A Little-Known Property of Flax fiber

Although less well known than its other properties, sound insulation is a notable characteristic of flax. Flax’s long, flexible fibers act as natural shock absorbers, absorbing sound waves and reducing reverberation. This ability to absorb sound makes flax a relevant choice in applications where noise control is crucial.

Case in point : the use of acoustic linen panels in spaces such as recording studios, cinemas or even modern offices is becoming increasingly common. These panels offer an elegant, environmentally-friendly solution for attenuating unwanted noise and improving the sound environment.

Thermal conductivity and use in insulation

Flax also demonstrates interesting properties in terms of thermal conductivity. Hollow flax fibers act as natural thermal barriers, limiting heat transmission. This makes it a suitable material for thermal insulation in construction applications, helping to maintain stable internal temperatures.

Case in point : Flax thermal insulation is used in green construction to improve the energy efficiency of buildings. These insulations offer a natural and sustainable alternative to traditional synthetic materials.