Flax fiber, one of the oldest fibers used by mankind, embodies timeless prestige, thanks to its unique properties and remarkable chemical composition. This plant fiber, extracted from the stems of the linum usitatissimum plant, is appreciated not only for its durability and aesthetics, but also for its sophisticated chemical structure, which gives it exceptional functional and environmental qualities.

Chemical composition of flax fiber

Flax fiber is mainly made up of cellulose, but its overall composition reflects a complex synergy between different biopolymers, giving the linen fiber its mechanical and acoustic characteristics. Here’s a detailed breakdown of the main components :

- Cellulose (65-85%) : Cellulose is the dominant structural component of linen fiber. It is a glucose polymer forming highly crystalline, longitudinally oriented microfibrils. This structure gives flax high mechanical strength and low extensibility. The cellulose in flax is characterized by a high degree of polymerization and crystalline organization, guaranteeing durability and wear-resistance.

- Hemicelluloses (10-20%) : Hemicelluloses are amorphous polysaccharides associated with cellulose. They play an essential role in microfibril bonding and fiber flexibility, contributing to moderate elasticity.

- Lignin (2-5%) : Lignin, an aromatic polymer, is present in low proportions in technical flax fibers. Its main function is to protect fibers against biological attack and to provide structural rigidity.

- Pectin (2-3%) : Pectins are polysaccharides rich in galacturonic acids. They bind individual fibers together, providing essential internal cohesion. During the retting process, pectins are broken down to facilitate fiber separation.

- Waxes and lipids (<2%) : These hydrophobic surface compounds give flax its soft feel and slight resistance to water.

- Mineral substances (1-2%) : These trace mineral elements, notably silica and calcium, play a role in fiber strength and heat resistance.

Proteins and associated components

Although the fiber linen is essentially made up of polysaccharides, it also contains residual proteins and enzymes. These elements, present in marginal quantities, play a role during plant development and the adhesion of primary fibers to surrounding tissues. The proteins identified include :

- Extensins: hydroxyproline-rich proteins involved in cell wall structuring.

- Lectins: Involved in cellular interactions and defense against pathogens.

- Hydrolytic enzymes: Active during the retting process, they lead to the degradation of pectins and hemicelluloses.

Physical and chemical properties of linen fibre : a precious and durable fiber

- Strength and lightness : Linen fiber combines high mechanical strength with low density, making it the fiber of choice for fine, durable textiles.

- Comfortable : Thanks to its high water absorption capacity (up to 20% of its weight in water), linen fiber offers unrivalled thermal comfort.

- Biodegradability (conditional) : Linen is entirely biodegradable and requires few chemical inputs for its cultivation, positioning it as an eco-responsible fiber.

Linen: a natural fibre symbolising refinement and prestige

Used since ancient times to make luxurious fabrics, linen continues to symbolize elegance and nobility. Its natural properties, combined with its reduced ecological footprint, make it a material of choice for major fashion houses and innovative textile designers. The slightly irregular appearance of its surface, combined with its soft yet robust feel, gives linen fabrics an authentic, timeless aesthetic.

Linen fiber is much more than just a textile material. It embodies a balance between natural technology and refined craftsmanship. Its chemical composition, dominated by cellulose but enriched with strategically organized auxiliary compounds, makes it an exceptional fiber, at the crossroads of science and art.

At Safilin, innovation is inseparable from tradition, and it is with this vision that the company places particular emphasis on research and development. Its dedicated department is constantly exploring new applications for linen fiber, to push back the frontiers of this exceptional natural material. Whether for sectors such as technical textiles, ecological composites or sustainable solutions, Safilin places innovation at the heart of its strategic development. By combining traditional expertise with advanced technologies, the company perfectly embodies its slogan “Tradition and Innovation”.

Plant fibres for a sustainable future

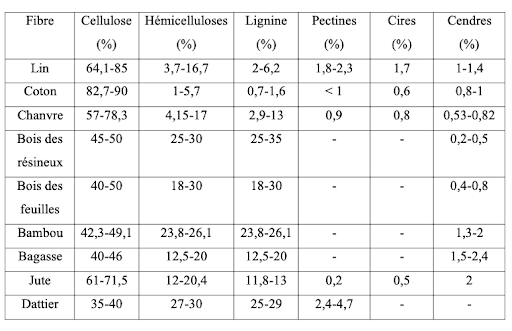

In addition to flax fiber, there are a plethora of other plant fibers. Here’s a non-exhaustive list to help you explore the world of plant fibers.

Abaca fibre : A substance derived from the leaves of the abaca tree (Musa textilis), a type of banana native to the Philippines. Once used to make ropes for ships, it could grow up to 3 meters long. Today, hemp pulp is used to make tea bags, sausage casings, banknotes, cigarette paper and high-end letters. It currently represents a major breakthrough in the automotive sector.

Coconut fiber: The coconut is covered with a lignocellulosic fiber. Due to its high lignin content, a natural polymer, it is considered a hard fiber. Stronger and less flexible than cotton, it is used in the production of upholstery for furniture and mattresses, brushes, rope and twine. The raw, short fibers that envelop the coconut are used to produce ropes, mattresses, brushes, geotextiles and car seats.

Cotton fiber: Cotton, composed of cellulose, is the most widely used natural material in the world. It remains the undisputed leader of the textile industry worldwide. Its softness, breathability, strength and other attributes make it the most widely used natural fiber in the world. It is used to manufacture a wide range of clothing and household textiles.

Hemp fiber : A substance marketed worldwide for the production of clothing, rope and paper. This highly resistant fiber is increasingly used in the production of construction materials and bioplastics for the automotive sector. Recent advances in wet-spinning technology are also helping to bring high-end products to market.

Jute fiber : Jute, extracted from the stems of the Corchorus capsularis and C. olitorius plants, is an extremely robust natural fiber. It is second only to cotton in terms of production and uses. Jute fiber is used to produce bags for packaging and transport, providing a source of livelihood for millions of small farmers.

Ramie: Ramie (Boehmeria nivea), also known as Chinese nettle, is a flourishing member of the nettle family. For thousands of years, its bark has been used to produce twine, thread and the fabric known as Chinese linen. It produces a white, silky and extremely strong fiber, whose absorbency and density are reminiscent of those of linen.

Sisal: A sublime plant suited to warm climatic conditions, it also thrives in dry areas. In many composite materials, sisal, which is unsuitable for garment production, replaces asbestos and fiberglass. Products made from sisal include biogas, pharmaceutical components and construction materials.